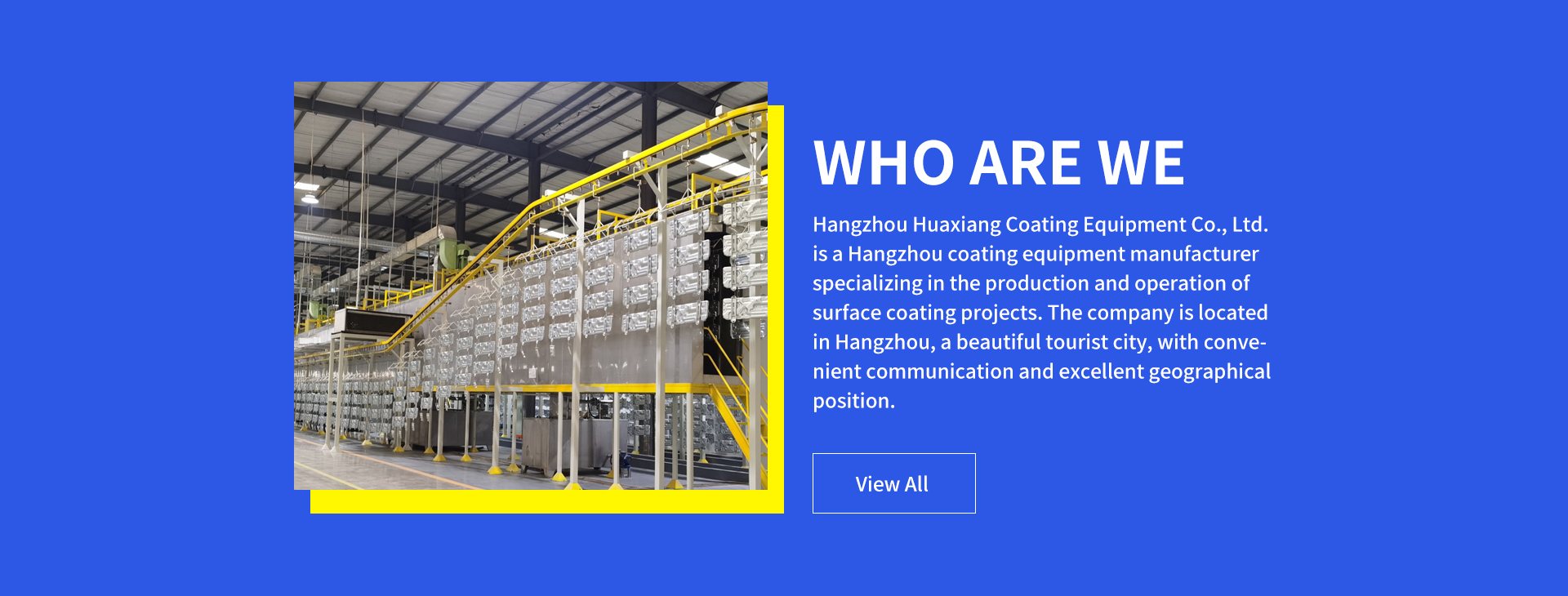

1. Automatic Powder Spraying Equipment Overview and Components

Automatic Powder Spraying Equipment uses robotic arms, programmable logic controllers (PLCs), and precision nozzles to apply coatings with minimal human intervention. Key components include a conveyor system, electrostatic spray guns, powder recovery units, curing ovens, and sensors for real-time adjustments. These systems ensure high-speed, consistent finishes ideal for large-scale production.

2. Applications of Automatic Powder Coating Systems

Widely used in automotive assembly lines for car body coatings, appliance manufacturing for oven or refrigerator finishes, and industrial machinery for corrosion protection. They also serve industries requiring high throughput, such as aerospace components and architectural metalwork.

3. Automatic Powder Spraying Equipment Pricing

Entry-level systems start at 50,000,whileadvancedroboticsetupswithAIintegrationexceed300,000. Costs depend on automation level (e.g., 6-axis robots add 25-40% to prices), brand (e.g., Durr, Eisenmann), and energy efficiency. Leasing or modular upgrades help manufacturers scale affordably.

4. How to Operate Automatic Powder Spraying Equipment

Program PLCs to match product dimensions and coating thickness (typically 60-120 microns). Maintain electrostatic gun voltage at 60-90 kV for optimal particle adhesion. Ensure conveyor speed aligns with curing oven temperatures (160-200°C). Clean nozzles daily and recalibrate sensors weekly.

5. Choosing the Best Automatic Powder Spraying System

Prioritize production volume: high-speed conveyors (5-20 m/min) suit mass production. Look for compatibility with diverse powders (epoxy, hybrid). Opt for systems with ≥95% powder recovery rates to reduce waste. Verify certifications like ISO 14001 for environmental compliance.

6. Safety Protocols for Automatic Powder Spraying Equipment

Install explosion-proof ventilation to manage combustible dust. Use light curtains or emergency stop buttons to protect workers near robotic arms. Ground all equipment and conduct monthly inspections of high-voltage components. Train staff on lockout-tagout (LOTO) procedures.

7. Design Efficiency of Automatic Powder Spraying Systems

Automated systems reduce labor costs by 70% and material waste by 40% compared to manual methods. Modular designs allow integration with existing production lines. Energy-efficient models cut power consumption by 25%, while IoT-enabled diagnostics predict maintenance needs.

8. FAQs About Automatic Powder Spraying Equipment

Q: Can robotic spray arms handle complex geometries?

A: Yes—6-axis robots with 3D vision systems coat intricate shapes uniformly.

Q: How long does installation take?

A: Basic systems require 2-4 weeks; advanced setups may take 8-12 weeks.

Q: Are automatic systems eco-friendly?

A: Yes—closed-loop powder recovery reduces emissions and waste.

Q: What’s the lifespan of automatic powder coating equipment?

A: 15+ years with regular maintenance and part replacements.

Q: Can these systems switch between powder types quickly?

A: Yes—color-changing modules enable transitions in under 10 minutes.

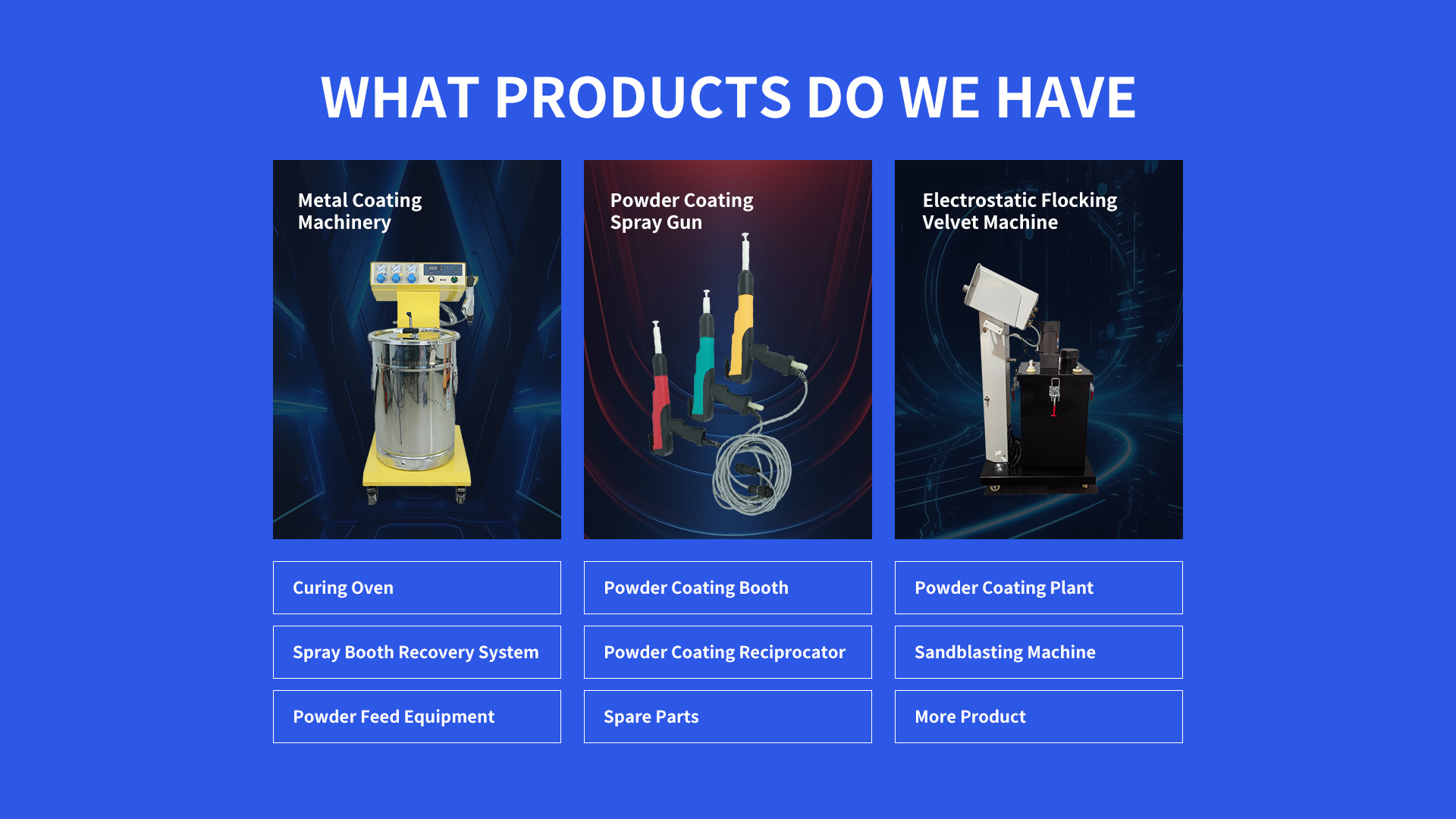

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com